STEEL DRY CONTAINER

Steel dry containers are the conventional type of covered body on pickups, which are used to protect the cargo while on transit. Fully fabricated with steel, the platform sub chassis and cross members are constructed with beams and channel. The top is finished using 4 mm thick steel sheets, which is stronger than the original platform that is typically made of wood and thin steel sheet cladding. The structure is made of hollow tubes as per required size, and the outer clad uses steel sheets. The joints are filled with sealants to give the appearance of a single sheet from outside. All corners are finished with aluminum angles to give a more aesthetic finish. The locks and hinges are of GI and will be of the same pattern as a sea-going container .

AIR DEFLECTOR

Air deflectors can be fitted above the driver's cabin which will provide an aerodynamic effect for the vehicle and also add to aesthetics.

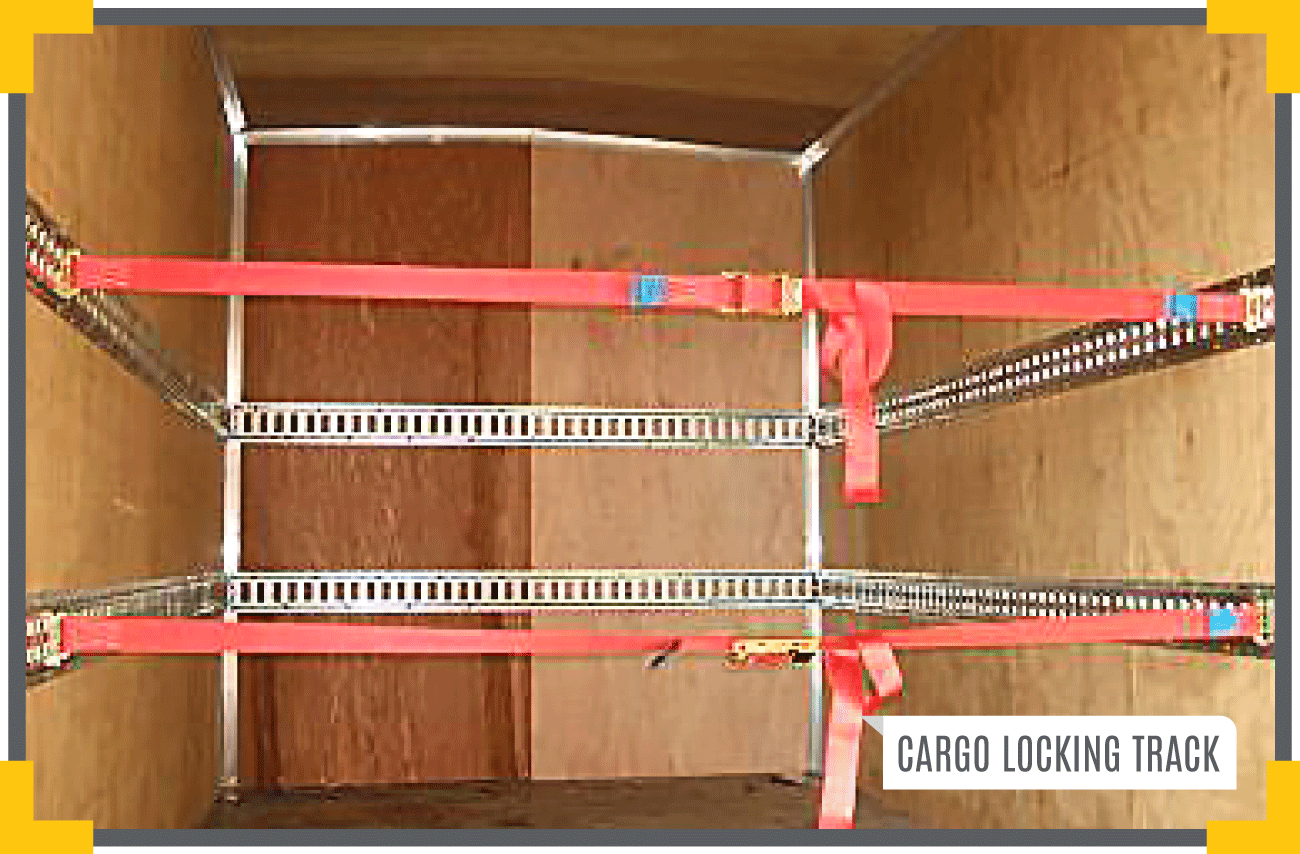

CARGO LOCKING TRACK

Loose cargo can be locked using cargo locking tracks and belts, which are tied to the wall of the container to prevent movement of cargo during transit.

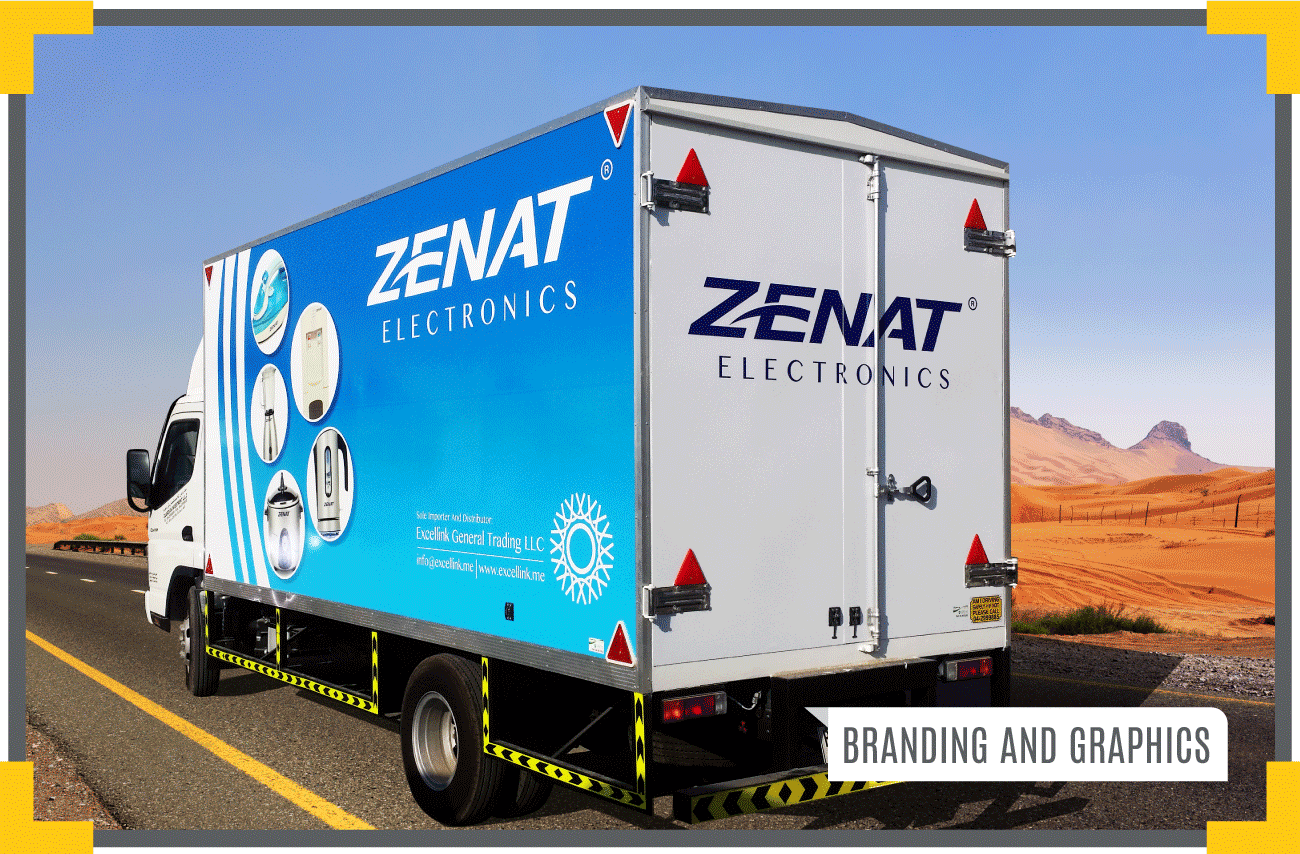

BRANDING AND GRAPHICS

The vehicles maybe branded using graphics that is highly effective form of advertising with only a normal cost compared to other forms of advertising.

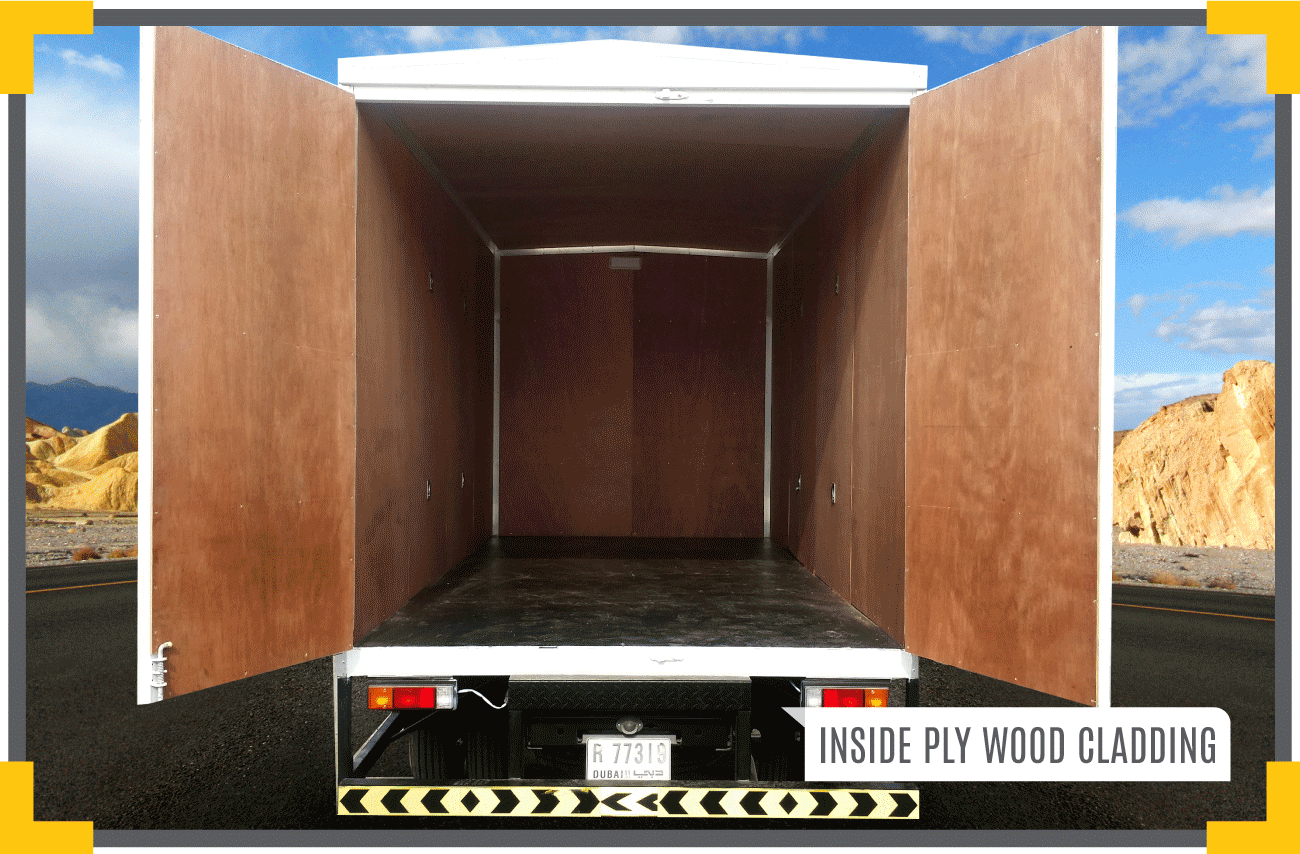

INSIDE PLY WOOD CLADDING

The interiors of these containers can be cladded with plywood, which will help avoid any damage to the cargo and will give a better appearance.

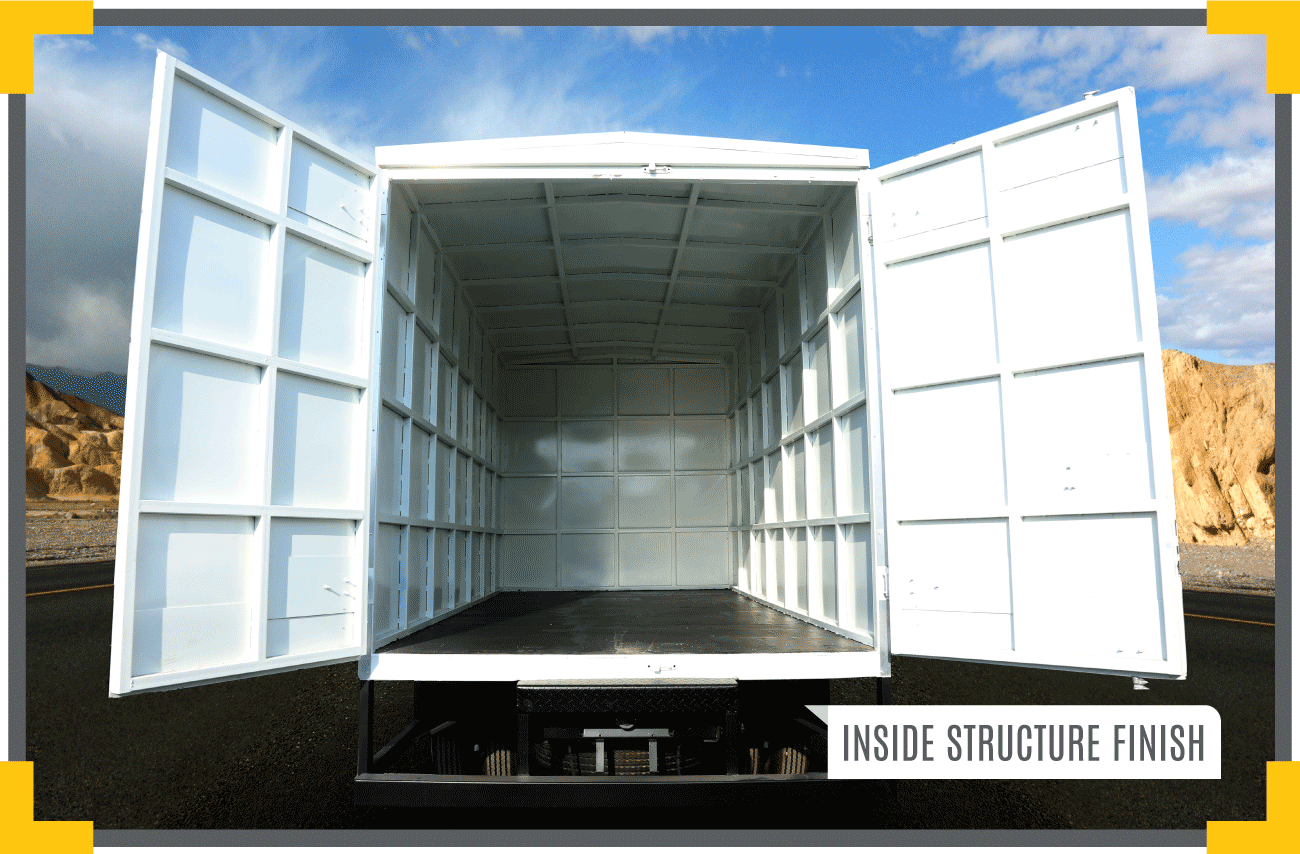

INSIDE STRUCTURE FINISH

The standard pattern inside the container is completed using steel structures that are painted while the wall joints are filled with synthetic sealant.

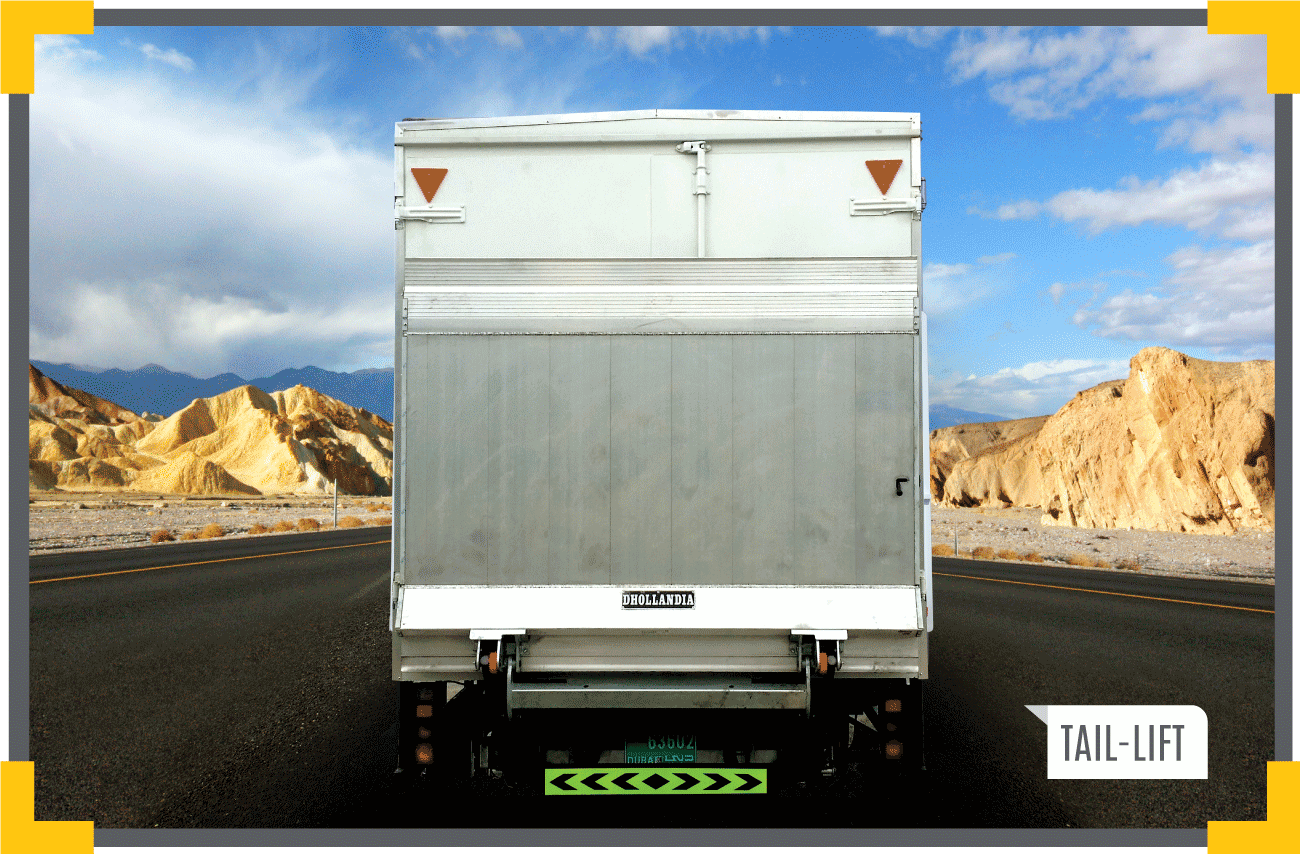

TAIL-LIFT

Tail-lift is a hydraulic operated platform that helps to lift up the cargo from ground level to the pickup platform level vice versa.